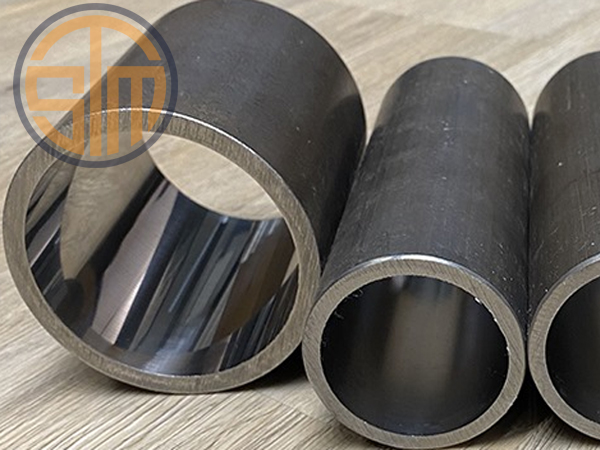

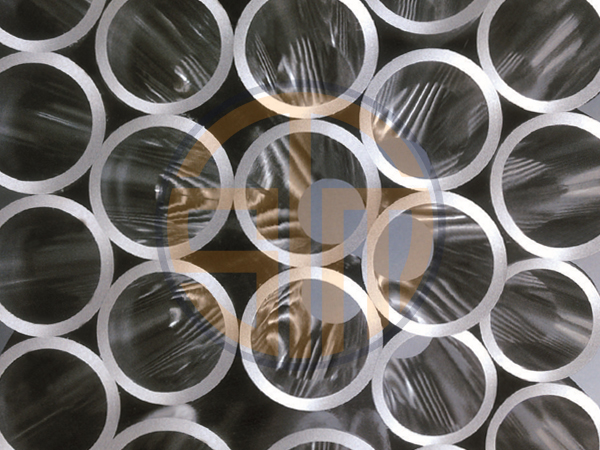

Cold Drawn - Skived & Roller Burnished, Honed Tubes Boring and turning tubes, machined honed tubes, seamless honed tubes, machined honed pipes, turning and boring honed tubes.

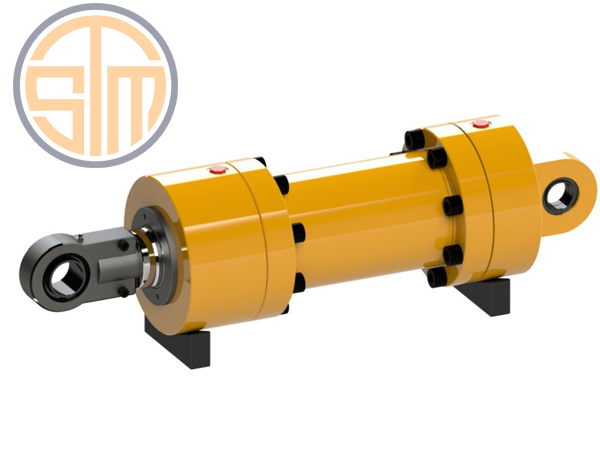

Skiving And Roller Burnishing Is A Two-Part, One-Pass Process That Removes Stock With Skiving Knives, Then Cold-Works Metal Surfaces With Rollers To Achieve The Highest Surface Finish Tolerances. This Process Is Commonly Used To Finish Hydraulic And Pneumatic Cylinders. Another Is Called Honing. Honing Is An Operation That Is Used Primarily To Improve The Surface Finish Of Holes Produced By Processes Such As Boring, Drilling, And Internal Grinding. The Honing Tool Consists Of A Set Of Aluminum Oxide Or Silicon-Carbide Bonded Abrasive Sticks, Usually Called Stones.

Skiving Roller Burnishing / Honed Tubes manufacturing process flow under :-

hydraulic cylinder, pneumatic cylinder,Jack, cylinder barrel,and and all pipes have requirement for tolerance.Finishing of cylinders for internal combustion engines, air bearing spindles and gears, used in oil, telecom, power plants, general engineering purposes, electrical industries and for various hydraulic applications like Hydraulic Cylinder, Hydraulic Jack, hydraulic oil cylinder pneumatic cylinder, petrifaction oil pump, coal mine, engineering machinery, crane and transport machinery, auto transmission axes, plastic machinery, engineering machinery, crane and transport machinery, auto transmission axes, plastic machinery, hydraulic oil cylinder, pneumatic cylinder, absorber, spin printing and dyeing, forklift, pump barrels, etc.

| BK | BKS | GBK | NBK | Q+T |

| +C | +SR | +A | +N | Q+T |

| Cold drawn | Stress relieved | Annealed | Normalized | QUENCHED + TEMPERED |

| Manufacture method | Cylinder ID(mm) | Length(m) | Straightness(mm/m) | Toleranceon ID | Roughness(μm) |

| Cold drawn | 40-420 | ≤16M | 0.2-0.5 | Depends on requirement | 0.8-1.6 |

| cold drawn - honed | 40-420 | 12M | 0.2-0.3 | H8-H9 | 0.2-0.8 |

| Cold drawn - skived & burnished | 40-420 | 9M | 0.2-0.3 | H8-H9 | ≤0.4 |

| Final Supply Condition | Cold finished(Hard)(BK) | Cold drawn and stress-relieved (BK+S or + SR) | Hardness HB | |||

| Parameters | T.SobN/mm2 | Elongation δ5% | T.S obN/mm2 | Y.S OsN/mm2 | Elongation δ5% | |

| 20# (A106B, ST45, E255) | ≧550 | ≧8 | ≧520 | ≧375 | ≧12 | 175 |

| 45#(CK45) | ≧650 | ≧5 | ≧600 | ≧500 | ≧10 | 190 |

| Q345B(ST52, E355) | ≧640 | ≧5 | ≧600 | ≧520 | ≧15 | 190 |

| 25Mn | ≧640 | ≧5 | ≧600 | ≧510 | ≧15 | 195 |

| 27SiMn | ≧840 | ≧5 | ≧760 | ≧610 | ≧10 | 220 |

| Material | C% | Mn% | Si% | S% | P% |

| 20# | 0.17-0.23 | 0.35-0.65 | 0.17-0.37 | ≤0.035 | ≤0.035 |

| ST45 | ≤0.21 | ≥0.4 | ≤0.35 | ≤0.025 | ≤0.025 |

| E255 | ≤0.21 | 0.4-1.1 | ≤0.35 | ≤0.025 | ≤0.025 |

| 45# | 0.42-0.50 | 0.50-0.80 | 0.17-0.37 | ≤0.035 | ≤0.035 |

| Q345B | ≤0.20 | ≤1.70 | ≤0.50 | ≤0.035 | ≤0.035 |

| E355 | ≤0.22 | ≤1.6 | ≤0.55 | ≤0.025 | ≤0.025 |

| ST52 | ≤0.22 | ≤1.6 | ≤0.55 | ≤0.04 | ≤0.04 |

| 25Mn | 0.22-0.29 | 0.70-1.0 | 0.17-0.37 | ≤0.035 | ≤0.035 |

| 27SiMn | 0.24-0.32 | 1.10-1.40 | 1.10-1.40 | ≤0.035 | ≤0.035 |

| ID | Tolerance for ID (μm) | |||

| H7 | H8 | H9 | H10 | |

| 30 | +210 | +330 | +520 | +840 |

| >30-50 | +250 | +390 | +620 | +1000 |

| >50-80 | +300 | +460 | +740 | +1200 |

| >80-120 | + 350 | + 540 | +870 | +1400 |

| >120-180 | +400 | +630 | +1000 | +1600 |

| >180-250 | +460 | +720 | +1150 | +1850 |

| >250-315 | +520 | +810 | +1400 | +2100 |

| >315-400 | +570 | +890 | +1700 | +2300 |

Copyright All Rights Reserved © 2021. STERLING TUBES || Powerd by - Ravi Infosoft